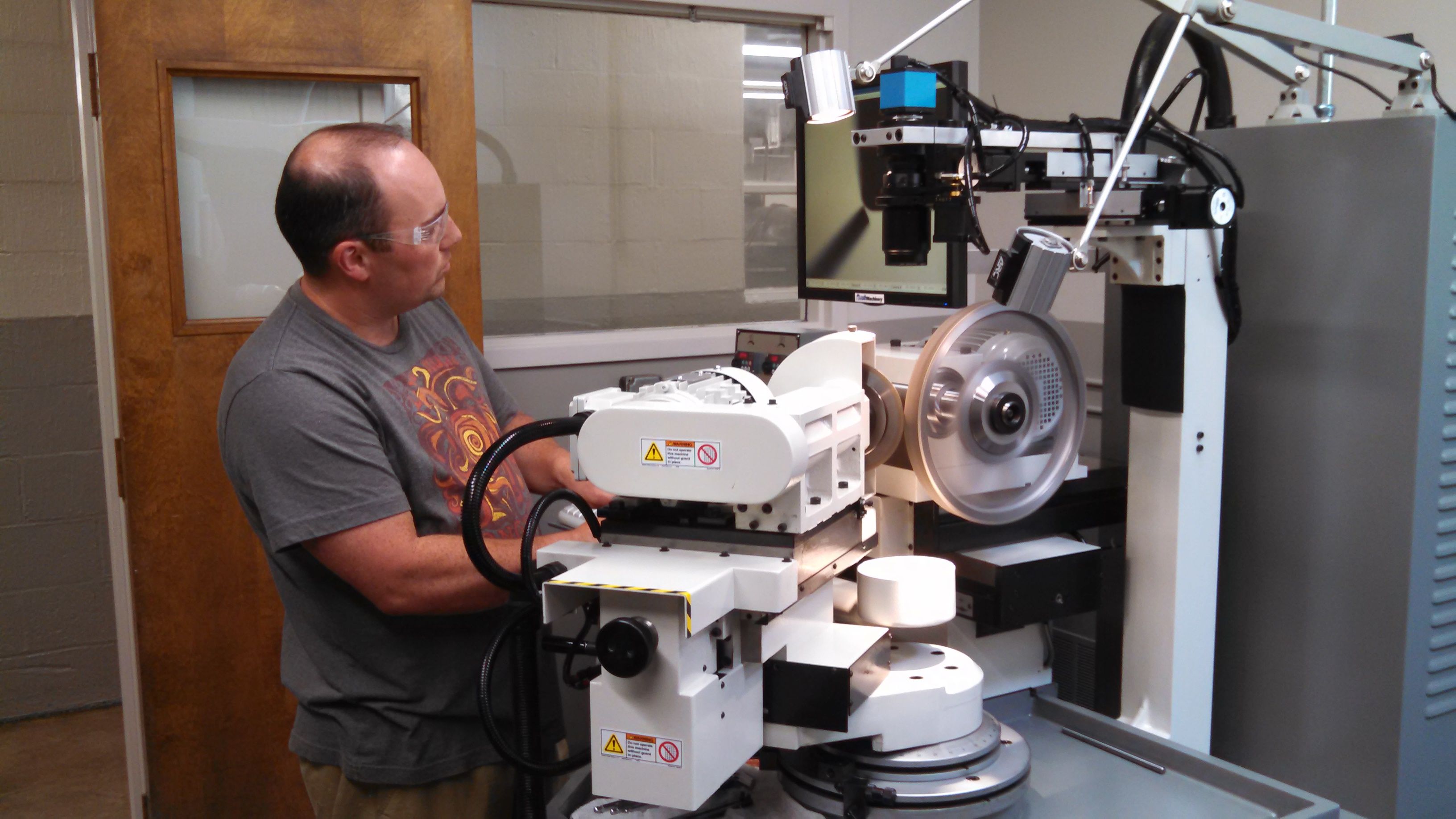

Triatic, Inc. manufactures high precision wheels and tools for aircraft and land based turbine manufacturers. This includes CBN form wheels for grinding turbine blades and other engine components.

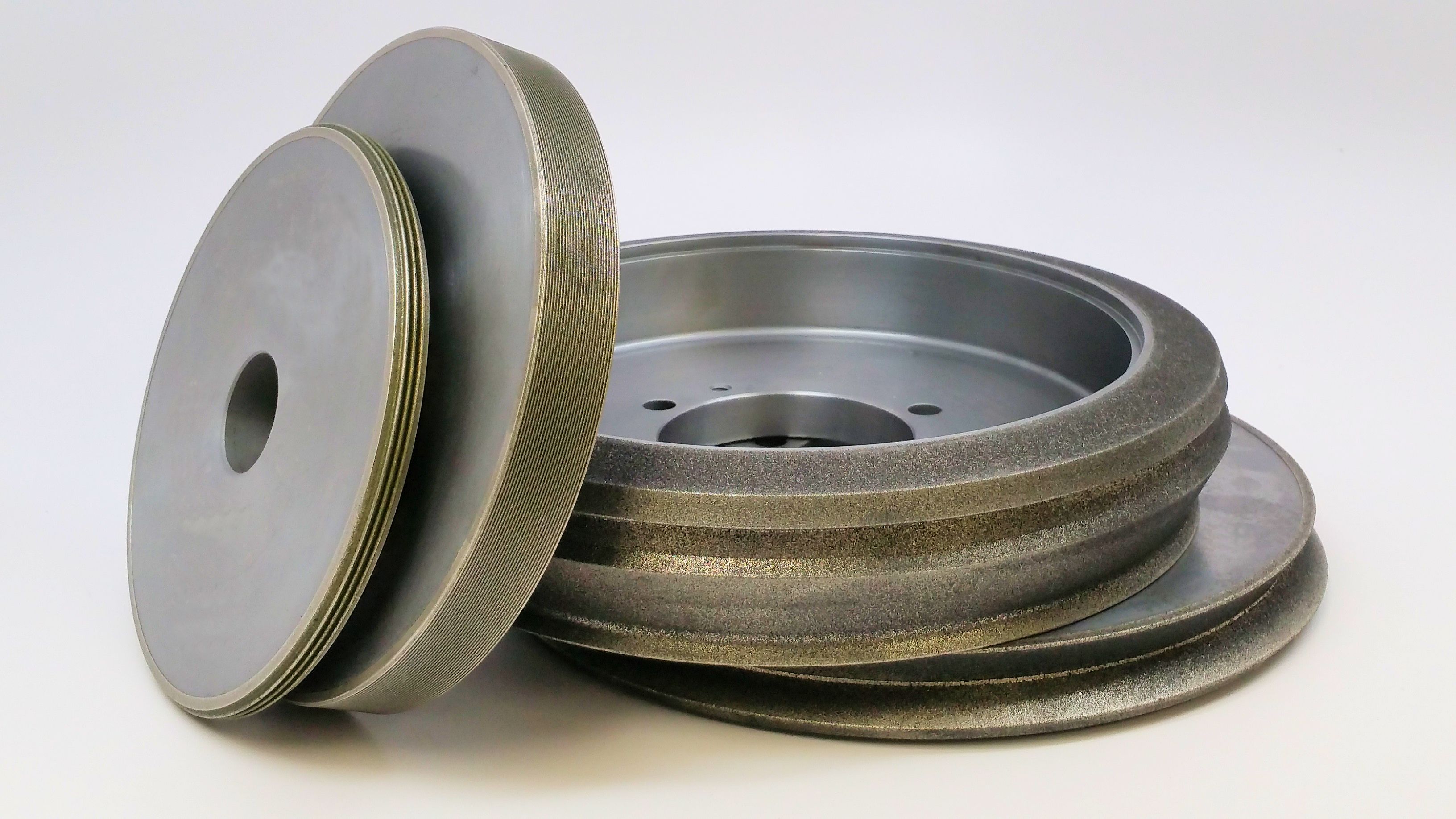

Electroplated CBN wheels and tools are the best choice for close tolerance form grinding applications requiring rapid stock removal in nickel alloys, cobalt alloys and other tough material removal applications.

Our highly regarded team of CBN grinding experts with more than 30 years of CBN grinding experience is ready to help you with the engineering, wheel design, coolant requirements and machine requirements necessary to provide you with a total package approach to your unique application.

Our electroplated wheels and tools are manufactured with tight tolerance forms. The lower initial cost compared to resin, vitrified and metal bonded superabrasive wheels offers a distinct financial advantage.

They are freer cutting resulting in higher material removal rates, less power required and reduced thermal damage to the workpeice.

The ability to hold form or profile from first cut essentially eliminates the time and expense associated with dressing.

Electroplated tooling has the distinction of being able to be stripped, reconditioned and replated providing even greater savings.