Machine Shop Rules and Etiquette: Know the Code

Published by Jim Driscoll on 24th Oct 2023

When starting any new job, there is a lot to learn on the first day. Your employer will likely share information about breaks, lunch hour, and office amenities. On top of this, you’ll also start meeting all your co-workers and remembering their names. While learning all the unspoken rules, the company will presumably cover their regulations and guidelines as well. No matter if it’s white- or blue-collar, every industry and job title has its own set of rules and etiquette.

Machine shop rules and etiquette are no exception. Some of these rules are applicable to any job setting, while others are industry-specific. Remember: practicing good manners will take you far in any setting. Don’t stress over this code-of-conduct—it’s there to keep everyone happy, safe, and productive.

The Rules

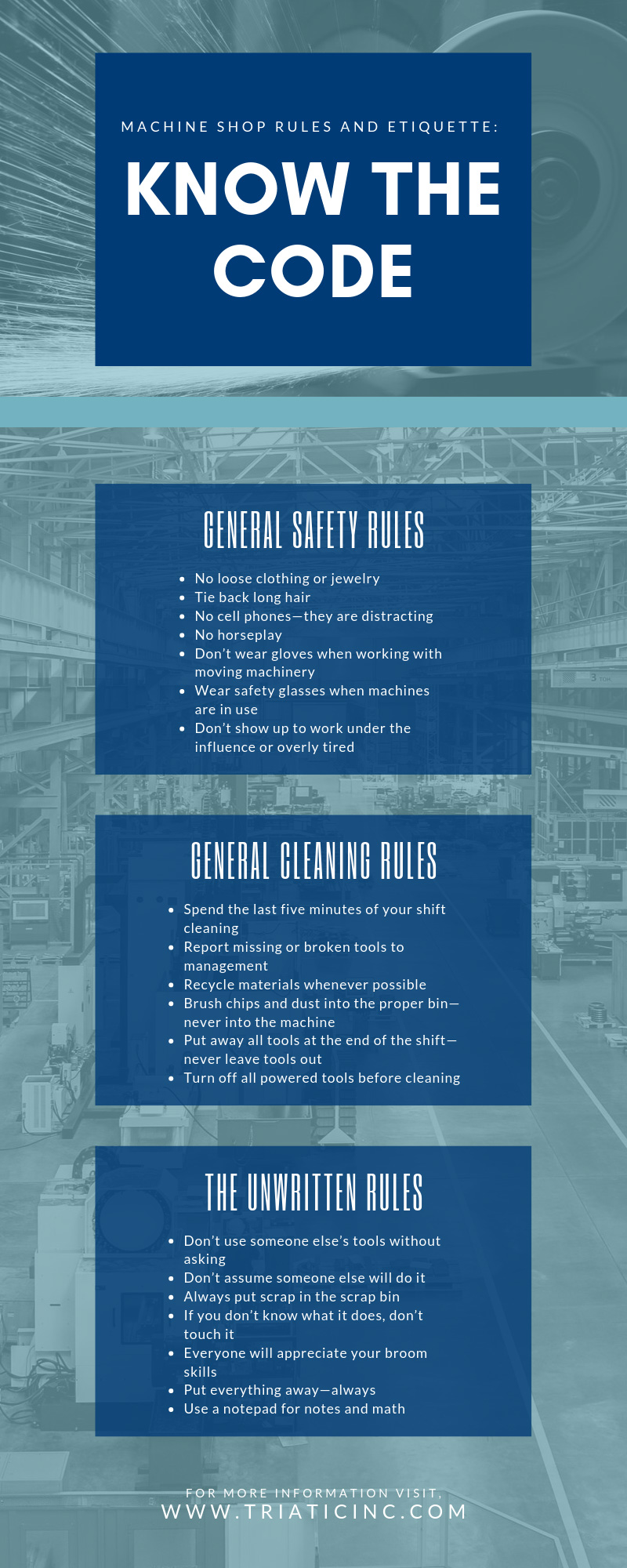

First, there are basic rules that every good machine shop has in place. Safety is the number one priority—no one wants injuries to occur while on the job. This is especially true of your employer. As such, your shop will have a set of rules to follow. The following are common guidelines found in most shops:

General Safety Rules

- No loose clothing or jewelry

- Tie back long hair

- No open-toed shoes—steel-toed boots or sneakers only

- Wear safety glasses when machines are in use

- Always have another person present when using tools, machines, or blades

- Don’t use compressed air to clean yourself off—it sends sharp particles flying.

- Don’t wear gloves when working with moving machinery

- No cell phones—they are distracting

- No horseplay

- Don’t show up to work under the influence or overly tired

If something should happen and an injury occurs, personnel should do the following;

- Immediately turn off all machines and tools

- Follow first aid procedures and call for medical help

- Don’t attempt to remove any foreign object from the harmed individual

- Report the incident to management

General Cleaning Rules

- Spend the last five minutes of your shift cleaning

- Report missing or broken tools to management

- Recycle materials whenever possible

- Brush chips and dust into the proper bin—never into the machine

- Put away all tools at the end of the shift—never leave tools out

- Remove all cutting tools from the mill or lathe before cleaning to avoid cuts

- Turn off all powered tools before cleaning

The Unwritten Rules

Now we are getting to the nitty-gritty protocols—the good stuff. Companies don’t officially sanction these rules, but they’re still important to follow. It’s common for the workers to set and enforce this set of rules. To gain an understanding of unwritten rules and how employers enforce them, consider major league baseball. The MLB has a historic and extensive list of unwritten rules; this includes not talking to a pitcher during a no-hitter, not showing up a pitcher after hitting a home run, avoiding running up the score, etc. If a player was to break one or multiple of these rules, they’ll find their teammates upset with them. Further, it’s likely the opposing team will correct the individual—and not necessarily in a nice manner.

These rules are born because someone, at some point, found the offending behavior upsetting and corrected it. In the workplace, crass, rude behavior or violence is not acceptable, and you should expect a manager or coworker to let you know you are doing something wrong. Being a good coworker and employee is the aim of the rules. So, to keep the peace among workers, learn and follow the unwritten rules. Every shop will have its own specific list, but common standards include:

- Don’t use someone else’s tools without asking

- If you need to borrow a tool more than twice, it’s time to buy one

- If you borrow a company tool from someone else’s bench, leave a note saying you took it

- Don’t assume someone else will do it

- Stay out of it—no matter what, if it doesn’t directly concern you, don’t involve yourself

- If you drop or break a tool, tell someone—it’s worse if you cover it up

- You’re accountable for your mistakes—learn from them and help solve the problem

- Always put scrap in the scrap bin

- Don’t offer advice to someone on how to do their job unless they ask

- If you don’t know what it does, don’t touch it

- Questions are good, but don’t keep asking the same questions over and over

- Keep your fingers out and away from machines

- Clean up like you own the place—don’t use the air hose doesn’t

- Everyone will appreciate your broom skills

- Don’t ever grab metal chips or flakes with your bare hand

- Learn how to complete a task before trying to do it fast

- Don’t drop a pallet or make a loud noise without announcing it first—scaring a machinist while they’re next to a moving tool can cause accidents and injuries

- Put everything—always

- Use a notepad for notes and math

- Complain up, not sideways so things will get better.

- Get prescription safety glasses if you are a normal glasses wearer

- Don’t hand someone a part that hasn’t gone through deburring—this could harm them

- Be delicate with the precision machines and tools

- If you don’t know, ask someone

- A machine shop is a dangerous place, so remain alert at all times

- Go slow and take your time

- Trust your gut—if something feels off, ask someone before going forward

- Measure twice and cut once

Triatic knows how important it is to support machine shops and their protocols—official and unofficial. As such, we strive to provide your business with the industry best diamond and CBN wheels and tools. Our offering of quality, precision products, ensures your workers can use them in a safe and efficient manner. From diamond abrasive discs to countersinks, take a moment to browse our inventory to find whatever tools you may need. If you have any questions or require assistance choosing the best tool for your specific application, feel free to contact our team. One of our expert team members will be happy to assist you.