What Makes Super Abrasives Super?

24th Oct 2023

Super abrasives—the name sounds amazing and so dynamic! It makes you wonder what makes super abrasives so…super. At present, there are two super abrasives, and both are hard, durable, and easy to work with. Many machinists in various industries use super abrasives to make precision cuts out of very hard materials, such as steel and stone.

Meet the Super Abrasives

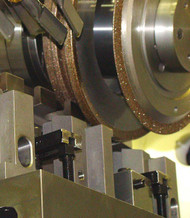

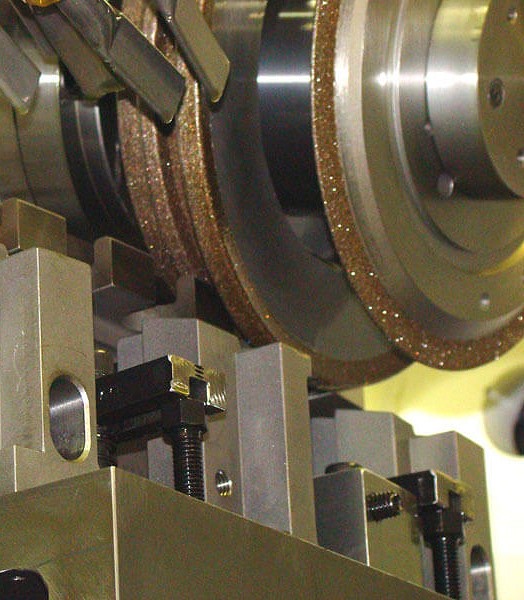

The so-called super abrasives are two hard elements that can cut and grind dense, high tempered metals and natural materials like granite. Their properties allow them to cut and grind at lower temperatures, thus lowering the chances of thermal damage or burns occurring. Since they are always harder than the material they are cutting, the removal rate is much higher. This allows super abrasives to last much longer than conventional materials and abrasives. Plus, you can re-plate and refinish the tools that have the super abrasives on them via the bonding process, rather than having to buy new.

Cubic Boron Nitride (CBN)

The same team that made synthetic diamonds created Cubic Boron Nitride or CBN. Similar to diamond making, CBN goes through a process called sintering. CBN has similar properties to diamond but with superior thermal and chemical stability, making it more suitable to cut super-hardened steel and metals. CBN shares the same crystalline structure as diamond, but instead of carbon atoms, it’s consists of alternately-bonded atoms of boron and nitrogen.

Diamond

Diamond is a naturally occurring mineral that is the hardest known material on earth. For decades, mining diamonds from the ground was the only way to find them. However, since the 1950s, labs started to make man-made synthetic diamonds. Beyond its use as a precious jewel for decoration, the diamond has many industrial uses, such as grinding and cutting. Professionals can use diamond as a cutting tool to cut non-metallic materials such as granite, gorilla glass, concrete, and ceramic tiles. For example, diamond coated jigsaw blades can cut precision holes in granite for sink hardware. The strength and precision of the blade make it ideal for creating precise features. Used in a CNC milling machine, a diamond-tipped contour tool cuts the slots and grooves in gorilla glass on smartphones as well. Diamond’s properties make it ideal for close tolerance and cutting and grinding with precision.